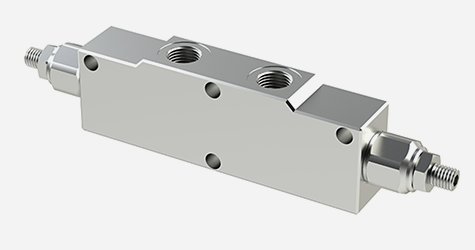

Our valves overcenter single series VBCL are designed to ensure the stability in the working position of a hydraulic actuator subject to the suspended load, and control the movement in one direction (usually the phase drop-down), leaving the opposite side powered by the free stream; thanks to the ports threaded BSPP-GAS can be installed in-line within the hydraulic system. Fueling the opposite line to the load, the line of the steering handles of the partial opening of the channel drop-down allowing you to control the movement of the actuator and avoiding the phenomenon of cavitation due to the action of a contrast to the gravitational force. A calibrated hole dampens the signal of the steering so that the opening and closing of the valve are carried out in a proportionate manner, avoiding the oscillations of the load. The balancing valve single VBCL also works as a valve, shock-resistant in the presence of pressure peaks caused by shock or heavy loads. For this to be possible it is necessary that the line of indentation on the distributor is connected to the exhaust. The VBCL is a valve is not compensated: any residual pressure on the line to indent in contrast, the opening of the valve alzandone the calibration values and handling. The use of this type of valve is, therefore, recommended in systems with distributors with the cursor at the centre of the open. The hydraulic seal is a fundamental characteristic of the balancing valves. To ensure the best performance, the Oleoweb he realizes the internal components of the valve of high-strength steel, hardened and ground, and, during the production process, to make sure the dimensions and geometric tolerances of the organs of the estate, as well as the seal itself when the valve is assembled. The VBCL are balancing valves parts-in-body: all components are housing inside a hydraulic collector, a solution that allows to manage high flow rates while containing the overall dimensions. The manifold is made of stainless steel for pressures up to 350 bar and high wear resistance; it is protected from corrosion by zinc treatment and has worked on the six faces for a run more effective in surface treatment. For applications that are exposed to corrosive agents, particularly aggressive (e.g. marine applications) available on request) treatment of Zinc-Nickel. Valves VBCL they are available in sizes from BSPP 1/4” BSPP 3/4” for course work recommended for up to 120 lpm. Are available on request in different fields of calibration and pilot ratios and a tamper-proof system of the calibration. For optimal operation it is recommended that you set the balancing valves to a value 30% higher than the maximum load.

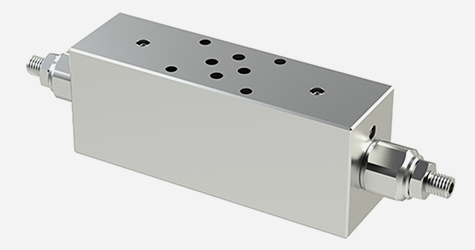

Our valves overcenter Oleoweb series VBCS are control valves drop-down movement and a double. Through these valves is therefore possible to handle loads of bidirectional ensuring the stability in the working position and monitor the movement even in the presence of gravity loads that do not generate pressure. The body of the valve with double flange Cetop 3 allows the use of these valves in hydraulic systems on the basis of Cetop 3, installed between the base modular (Oleoweb series BP3, BS3 or BM) and the solenoid directional valve. The maximum working pressure is 350 bar and the maximum recommended capacity of 40 l/min. The motion control is achieved thanks to the gradual opening of the line-of-return actuator, open-which is managed by the pilot pressure on the branch opposite, and that generates a back pressure to moderate the speed of movement of an actuator in the presence of a gravity load, thus preventing the appearance of the phenomenon called cavitation. The balancing valves VBCS can also be used for the function of the valve, shock-resistant, protecting the hydraulic system and the mechanical structure to which it is connected by any pressure spikes that may occur due to excessive loads of accidental knocks. This function is only possible if the line of return to the valley of the valve is connected to the exhaust. The VBCS is a balancing valve non-compensated: any pressures add up to the calibration of the valve and contrast the opening. For this type of valve is, therefore, recommended for use in systems that require a directional control valve cetop with the cursor at the centre of the open, with the use connected to the exhaust in the neutral position. Particular care is taken in by Oleoweb in the construction and verification of the internal components that make up the hydraulic seal, verifying dimensions and tolerances, as well as the seal itself when the valve is mounted. The body and the external components are made of high-strength steel and are protected against corrosion by zinc treatment. The processing of the body on the six faces ensures an optimal execution of the surface treatment for the benefit of its effectiveness. For applications that are exposed to corrosive agents, particularly aggressive (e.g. marine applications) available on request) treatment of Zinc-Nickel. There are several fields of calibration and different pilot ratios in order to better adapt to all types of application. Using a plastic cap is also possible to seal the calibration protecting it from tampering. For optimal operation it is recommended that you calibrate the balancing valve a value 30% higher than that of the maximum load of work.

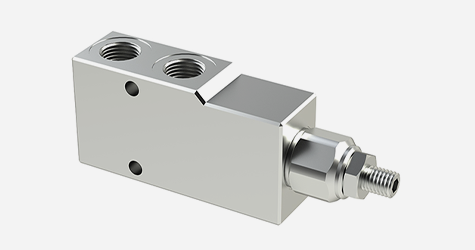

The overcenter valves of the VBCA series are double-acting control valves designed to manage the movement of hydraulic cylinders in both directions. These double-chamber balancing valves are ideal for applications that require stability in the working position and precise control of hydraulic actuators on both sides of the power source. Typical applications include boom lifts, telescopic wheel loaders, and locking the rotation of hydraulic motors. In hydraulic systems, these valves are installed to control the opening branches connected to the cylinder’s return line. Dual check valves in the flow path allow unrestricted supply. With a specific pilot ratio, the pressure needed to open the valve is lower than the set pressure. When the opposite line is pressurized, the valve partially opens the descent line to control actuator movement, counteract gravity, and prevent cavitation. The VBCA valve also acts as a pressure relief valve to protect mechanical components from damage caused by shocks or overloads, provided the indentation line is connected to the exhaust. This non-compensated balancing valve adds any residual pressure in the indentation line to the adjustment value, making it best suited for use with open-center distributors connected to the exhaust in the neutral position. High-strength, hardened, and ground steel is used for durability, with precise machining ensuring optimal sealing and performance. All components are integrated within a compact hydraulic manifold, allowing for high flow rates and reduced dimensions. The body and external parts are corrosion-resistant, treated with zinc, and for harsher environments, a Zinc-Nickel treatment is available upon request. The robust steel construction ensures long-lasting reliability and wear resistance. Available in BSPP 3/8” size, these valves handle pressures up to 350 bar and flow rates up to 40 l/min. For best performance, calibration should be set 30% above the maximum working load. Multiple calibration ranges and pilot ratios are offered for application flexibility, and a plastic cap can be used to secure the settings against tampering.

Our balancing valves constitute a fundamental component of the hydraulic circuits of those applications that handle suspended loads. The balancing valves Oleoweb VBCF are designed to achieve the best control of the loads in the working conditions that provide boosts, gravity on the actuators, such as cylinders or hydraulic motors. The valves overcenter VBCF are double-acting control, that is, the load in both directions of the flow; these are valves flangiabili, apploicabili, therefore, directly on the actuator with a consequent reduction of the phenomenon of hysteresis. The livelihood of a load gravitazinale is therefore one of the fundamental tasks of the balancing valves. To ensure the best performance in terms of supporting the load, Oleoweb particular attention to the tightness of its balancing valves, making the components of high-strength steel, hardened and ground, and by carefully checking the size and teolleranze as well as the tightness of the valves once assembled. Another main task of the valves overcenter is the control of the movement of the actuator. Thanks to the pilot ratio, it is possible to unlock the load at a lower pressure than that of the setting of the valve. For the balancing valves Oleoweb are available in different pilot ratios. The spring also allows a gradual opening of the area of passage of the fluid, allowing the control of the movement of the actuator even in the presence of loads to be negative and thus avoiding the occurrence of the phenomenon of cavitation. For optimal operation it is recommended that you calibrate the balancing valve a value 30% higher than that of the maximum load of work. Using a plastic cap is also possible to seal the calibration protecting it from tampering. The balancing valves VBCF can also perform the function of the shock valves protect the structure is connected to the actuator from damage caused by sudden surges in pressure due to, for example, loads that are too high or accidental bumps. For this to be possible it is necessary that the line of indentation on the distributor is connected to the exhaust. The VBCF is a balancing valve not offset any residual pressure in the lines to return to contrast the opening of the valve alzandone the calibration value, and pilot pressure required to open it. For this reason, this type of valve is best suited to be installed downstream of distributors with the cursor at the centre of the open, with the use connected to the exhaust in the neutral position. The balancing valvesOleoweb VBCF are valves parts in the body: the components are housing inside a hydraulic collector. This solution can handle high flow rates while containing the overall dimensions. The valve body and the external components are made of high-strength steel and are protected against corrosion by zinc treatment. The processing of the body on the six faces ensures an optimal execution of the surface treatment for the benefit of its effectiveness. For applications that are exposed to corrosive agents, particularly aggressive (e.g. marine applications) available on request) treatment of Zinc-Nickel. The steel body allows you to work with operating pressures up to 350 bar and ensures a high wear resistance to the benefit of reliability and service life of the valve. The valves VBCF are available in sizes from BSPP 1/4” BSPP 1/2” for flow rates up to 60 l/min.

Our valves overcenter series VBCL are valves drop-down control, single control, therefore, the movement of the cylinder in one direction (usually the descent stage) while on the opposite side of the actuator is powered by the free stream. They are suitable for applications where it is necessary to ensure the stability in the working position and to control the descent stage of a suspended load, and subject to the gravitational force. Within a hydraulic circuit these balancing valves single are installed in such a way that the branch opening in both controlled the reentry of the cylinder, while being sent check valve allows power to flow free. Thanks to a reduction ratio between the line of the load and the pilot hydraulic (pilot ratio), the pressure necessary to open the valve, overcenter is lower than that of the calibration. Feeding the line opposite to that of the load, it acts on the sense line which has the task of dealing with the partial opening of the line of descent and allow codì control the movement of the actuator counteracting the gravitational force and avoiding the phenomenon of cavitation. A calibrated hole on the line of the steering also ensures the opening and closing of the valve takes place in a gradual manner, avoiding the oscillations of the load. The balancing valve single VBCL also works as a pressure relief valve to protect the structure is connected to the actuator: in case of increase of pressure caused by the load is too high, or from accidental knocks, the valve opens to the calibration value is reached by downloading the excess pressure. For this to be possible it is necessary that the line of indentation on the distributor is connected to the exhaust. The VBCL is a balancing valve and hydraulic not offset any residual pressure on the line to indent in contrast, the opening of the valve and increasing the value of the calibration and of the pilot pressure required to open it. For this reason, this type of valve is best suited to be installed downstream of distributors with the cursor at the centre of the open, with the use connected to the exhaust in the neutral position. For the support of the load, the resistance is an essential characteristic for this type of valve. For this reason, the internal components of the valve, overcenter Oleoweb they are constructed of high-strength steel, hardened and ground, and during the production process is carefully checked the dimensions and geometric tolerances of the organs of touch, as well as the seal itself when the valve is mounted. The balancing valves single VBCL are valves parts in the body: all the components are housing inside a hydraulic collector. This solution can handle high flow rates while containing the overall dimensions. The body and the external components are made of high-strength steel and are protected against corrosion by zinc treatment. Oleoweb also works the valve body on the six exterior faces to ensure optimal execution of the surface treatment for the benefit of its effectiveness. For applications that are exposed to corrosive agents, particularly aggressive (e.g. marine applications) available on request) treatment of Zinc-Nickel. The steel body also ensures a high resistance to wear and tear for the benefit of reliability and service life of the valve. Its shape allows for easy installation of pipes with fittings to the eye (banjo). The hydraulic valves VBCL they are available in sizes from BSPP 1/4” BSPP 3/4”. Can work with a maximum pressure up to 350 bar, and is recommended for use, depending on the size you choose, for flow rates up to 120 l/min. For optimal operation it is recommended that you calibrate this balancing valve a value 30% higher than that of the maximum load of work. There are several fields of calibration and different pilot ratios in order to better adapt to all types of application. Using a plastic cap is also possible to seal the calibration protecting it from tampering.

The VBCD series valves are valves control the descent and movement (or double overcenter). Their action stops the load and controls its movement in both directions and are suitable for applications where it is necessary not only to control the descent phase of a suspended load subject to gravitational force, but also to guarantee stability in the actuator’s working position in the presence of bi-directional loads, as is the case with reversible hydraulic motors, for example. The pilot line manages the partial opening of the downstream channel, allowing the actuator’s movement to be controlled and avoiding the phenomenon of cavitation. The valve also acts as a shock absorber in the presence of pressure peaks caused by shocks or excessive loads. In order for this to be possible, the return line on the valve must be connected to unloading. The VBCD is a valve is not compensated and its use is recommended in systems with open-centre spool valves. Hydraulic sealing is a key feature for balancing valves. To ensure the best performance, Oleoweb manufactures the internal components of its valves from high-strength, hardened and ground steel and, during the production process, carefully checks the dimensions and geometric tolerances of the sealing components, as well as the seal itself when the valve is assembled. VBCDs are balancing valves parts-in-body, a solution that allows high flow rates to be handled with reduced overall dimensions. The manifold is made of steel for operating pressures up to 350 bar and high resistance to wear; it is protected from corrosion by a galvanising treatment and is machined on all six faces for more effective surface treatment. For applications exposed to particularly aggressive corrosive agents (e.g. marine applications) a Zinc-Nickel treatment is available on request. The valves VBCD are available with threaded ports from BSPP ¼” to BSPP ¾” for recommended flow rates up to 120 lpm. Different setting ranges and pilot ratios are available on request, as well as a calibration tamper proof system. For optimum operation it is recommended to set the balancing valves to a value of 30% higher than the maximum working load.