Headquartered in the UAE, this trusted supplier provides high-quality fittings and adapters essential for hydraulic and industrial hose assemblies. With a comprehensive inventory, they cater to a wide spectrum of industries, offering products that comply with global standards and meet diverse application needs.

Product Highlights

SAE 100R1AT / EN 853 1SN

SAE 100R2AT / EN 853 2SN

4SP/04-10

4SH/12-32, R12/20-24

SAE 100R7

SAE 100R8

Teflon

Interlock – R13

Multi-spiral hoses

NPT, BSP, JIC, and Metric

Available in Male, Female, and Elbow types

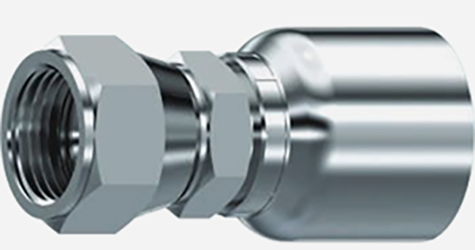

One-piece fittings for simplified assembly and improved sealing

Quick-action couplings for fast and secure connections

Safety accessories to enhance operational reliability

Polyfit’s extensive product range is engineered to support secure, efficient, and leak-proof fluid transfer systems, making them a preferred partner for fluid power and industrial connection solutions across the region.