| CODE | Material Description | |

| 6V200M2FG | 2-Way Valve Manifold | |

| 6V200M3FG | 3-Way Valve Manifold | |

| 6V200M4FG | 4-Way Valve Manifold | |

| 6V200M5FG | 5-Way Valve Manifold | |

| 6V200M6FG | 6-Way Valve Manifold | |

| 6V200M7FG | 7-Way Valve Manifold | |

| 6V200M8FG | 8-Way Valve Manifold | |

| 6V200M9FG | 9-Way Valve Manifold | |

| 6V200M10FG | 10-Way Valve Manifold | |

| 6V200M11FG | 11-Way Valve Manifold | |

| 6V200M12FG | 12-Way Valve Manifold | |

| 6V200M13FG | 13-Way Valve Manifold | |

| 6V200M14FG | 14-Way Valve Manifold | |

| 6V200M15FG | 15-Way Valve Manifold | |

| 6V200M16FG | 16-Way Valve Manifold | |

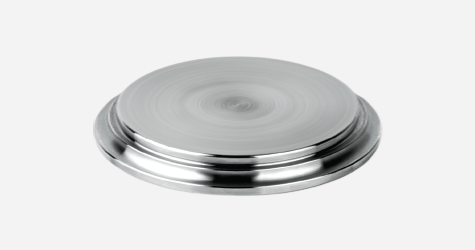

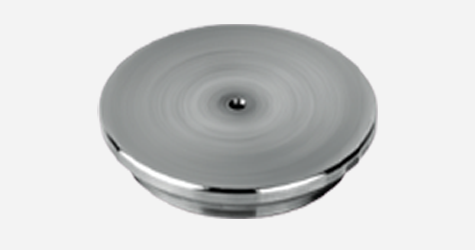

| P-6V0500M-R2 | Blanking Plate | |

| KOD | DISPLACEMENT (cm³/rev) | FLOW RATE – L/min (at 1500 rpm) | MAX. PRESSURE (Bar) | MAX. SPEED (rpm) | ADAPTOR SIZE | |

| R1PN 040 AX3/CX3 | 4 | 5.7 | 250 | 3000 | 1/2″ 40 mm | 3/8″ 35 mm |

| R1PN 061 AX3/CX3 | 6.1 | 8.7 | 250 | 3000 | 1/2″ 40 mm | 3/8″ 35 mm |

| R1PN 082 AX3/C3X | 8.2 | 11.8 | 250 | 3000 | 1/2″ 40 mm | 3/8″ 35 mm |

| R1PN 095 AX3/CX3 | 9.5 | 13.1 | 250 | 3000 | 1/2″ 40 mm | 3/8″ 35 mm |

| R1PN 119 AX3/CX3 | 11.9 | 17.1 | 250 | 3000 | 1/2″ 40 mm | 3/8″ 35 mm |

| R1PN 140 AX3/CX3 | 14 | 20.1 | 250 | 3000 | 1/2″ 40 mm | 3/8″ 35 mm |

| R1PN 168 AX3/CX3 | 16.8 | 24.1 | 250 | 3000 | 1/2″ 40 mm | 3/8″ 35 mm |

| R1PN 192 AX3/CX3 | 19.2 | 27.2 | 250 | 3000 | 1/2″ 40 mm | 3/8″ 35 mm |

| R1PN 229 AX3/CX3 | 22.9 | 32.9 | 210 | 3000 | 1/2″ 40 mm | 3/8″ 35 mm |

| R1PN 281 AX3/CX3 | 28.1 | 40.4 | 175 | 3000 | 1/2″ 40 mm | 3/8″ 35 mm |

| PRODUCT CODE | L | L1 | L2 | D | D1 |

|---|---|---|---|---|---|

| GDC-AK-32×40 | 15 | 5 | 5 | 40 | 32 |

| GDC-AK-35×45 | 15 | 5 | 5 | 45 | 35 |

| GDC-AK-40×50 | 15 | 5 | 5 | 50 | 40 |

| GDC-AK-45×55 | 15 | 5 | 5 | 55 | 45 |

| GDC-AK-50×60 | 15 | 5 | 5 | 60 | 50 |

| GDC-AK-50×65 | 15 | 5 | 5 | 65 | 50 |

| GDC-AK-55×65 | 15 | 5 | 5 | 65 | 55 |

| GDC-AK-60×70 | 15 | 5 | 5 | 70 | 60 |

| GDC-AK-60×80 | 15 | 5 | 5 | 80 | 60 |

| GDC-AK-63×75 | 15 | 5 | 5 | 75 | 63 |

| GDC-AK-65×80 | 15 | 5 | 5 | 80 | 65 |

| GDC-AK-70×85 | 15 | 5 | 5 | 80 | 70 |

| GDC-AK-75×90 | 15 | 5 | 5 | 90 | 75 |

| GDC-AK-80×95 | 15 | 5 | 5 | 95 | 80 |

| GDC-AK-80×100 | 15 | 5 | 5 | 100 | 80 |

| GDC-AK-85×100 | 20 | 9 | 5 | 100 | 85 |

| GDC-AK-90×105 | 20 | 9 | 5 | 105 | 90 |

| GDC-AK-90×110 | 20 | 9 | 5 | 105 | 90 |

| GDC-AK-100×115 | 20 | 9 | 5 | 115 | 100 |

| GDC-AK-100×120 | 20 | 9 | 5 | 120 | 100 |

| GDC-AK-110×130 | 20 | 9 | 5 | 130 | 110 |

| GDC-AK-115×130 | 20 | 9 | 5 | 130 | 115 |

| GDC-AK-120×140 | 20 | 9 | 5 | 140 | 120 |

| GDC-AK-125×145 | 20 | 9 | 5 | 145 | 125 |

| GDC-AK-125×150 | 20 | 9 | 5 | 150 | 125 |

| GDC-AK-130×150 | 20 | 9 | 5 | 150 | 130 |

| GDC-AK-140×160 | 20 | 9 | 5 | 160 | 140 |

| GDC-AK-150×170 | 20 | 9 | 5 | 170 | 150 |

| GDC-AK-160×190 | 25 | 9 | 5 | 180 | 160 |

| GDC-AK-170×200 | 25 | 9 | 5 | 200 | 170 |

| GDC-AK-180×210 | 25 | 9 | 5 | 210 | 180 |

| GDC-AK-200×245 | 30 | 9 | 5 | 245 | 200 |

| GDC-AK-220×270 | 30 | 9 | 8 | 270 | 220 |

| GDC-AK-230×280 | 30 | 9 | 8 | 280 | 230 |

| GDC-AK-250×300 | 30 | 9 | 8 | 300 | 250 |

| KOD | D | I | S | LF | D1 | D2 | D3 | D4 | S1 | S2 | L | L1 | F | a | CİVATA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PR 20 U | 20 | 50 | 16 | 17 | 56 | 46 | 25 | 24.1 | 19 | 21 | 80 | 25 | M16x1,5 | 9 | M8x20 |

| PR 25 U | 25 | 50 | 20 | 17 | 56 | 46 | 25 | 29.3 | 23 | 21 | 80 | 28 | M16x1,5 | 7 | M8x20 |

| PR 30 U | 30 | 60 | 22 | 23 | 64 | 50 | 32 | 34.2 | 28 | 26 | 94 | 30 | M22x1,5 | 6 | M8x25 |

| PR 35 U | 35 | 70 | 25 | 29 | 78 | 66 | 40 | 39.7 | 30 | 28 | 112 | 38 | M28x1,5 | 6 | M10x30 |

| PR 40 U | 40 | 85 | 28 | 36 | 94 | 76 | 49 | 45 | 35 | 33 | 135 | 45 | M35x1,5 | 7 | M10x35 |

| PR 50 U | 50 | 105 | 35 | 46 | 116 | 90 | 61 | 56 | 40 | 37 | 168 | 55 | M45x1,5 | 6 | M12x40 |

| PR 60 U | 60 | 130 | 44 | 59 | 130 | 120 | 75 | 66.8 | 50 | 46 | 200 | 65 | M58x1,5 | 6 | M16x45 |

| PR 70 U | 70 | 150 | 49 | 66 | 157 | 130 | 86 | 77.8 | 55 | 51 | 232 | 75 | M65x1,5 | 6 | M16x50 |

| PR 80 U | 80 | 170 | 55 | 81 | 178 | 160 | 105 | 89.4 | 60 | 55 | 265 | 80 | M80x2 | 6 | M20x55 |

| PR 90 U | 90 | 210 | 60 | 101 | 210 | 180 | 124 | 98.1 | 65 | 63 | 323 | 90 | M100x2 | 5 | M20x60 |

| PR 100 U | 100 | 235 | 70 | 111 | 234 | 200 | 138 | 109.5 | 70 | 65 | 360.7 | 105 | M110x2 | 7 | M24x65 |

| KOD | d | s | ı | D1 | D2 | S1 | L | a |

|---|---|---|---|---|---|---|---|---|

| S 20 N | 20 | 16 | 38 | 50 | 24.1 | 19 | 63 | 9 |

| S 25 N | 25 | 20 | 45 | 55 | 29.3 | 23 | 72.5 | 7 |

| S 30 N | 30 | 22 | 51 | 65 | 34.2 | 28 | 83.5 | 6 |

| S 35 N | 35 | 25 | 61 | 83 | 39.7 | 30 | 102.5 | 6 |

| S 40 N | 40 | 28 | 69 | 101 | 45 | 35 | 119 | 7 |

| S 45 N | 45 | 32 | 77 | 111 | 50.7 | 60 | 132 | 7 |

| S 50 N | 50 | 35 | 88 | 123 | 56 | 40 | 149.5 | 6 |

| S 60 N | 60 | 44 | 100 | 140 | 66.8 | 50 | 170 | 6 |

| S 70 N | 70 | 49 | 115 | 164 | 77.8 | 55 | 197 | 6 |

| S 80 N | 80 | 55 | 141 | 180 | 89.4 | 60 | 231 | 6 |

| S 90 N | 90 | 60 | 150 | 226 | 98.1 | 65 | 263 | 6 |

| S 100 N | 100 | 70 | 170 | 250 | 109.5 | 70 | 295 | 6 |

| KOD | D | I | S | D1 | D2 | D3 | D4 | S1 | L | L1 | L2 | a |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S 20 C | 20 | 38 | 16 | 53 | 27.5 | 24.1 | 4 | 13 | 64.5 | 27.5 | 3 | 9 |

| S 25 C | 25 | 45 | 20 | 64 | 33.5 | 29.3 | 4 | 17 | 77 | 33 | 4 | 7 |

| S 30 C | 30 | 51 | 22 | 73 | 40 | 34.2 | 4 | 19 | 87.5 | 37.5 | 4 | 6 |

| S 35 C | 35 | 61 | 25 | 82 | 47 | 39.7 | 4 | 21 | 102 | 43 | 4 | 6 |

| S 40 C | 40 | 69 | 28 | 92 | 52 | 45 | 4 | 23 | 115 | 48 | 5 | 7 |

| S 45 C | 45 | 77 | 32 | 102 | 58 | 50.7 | 6 | 27 | 123 | 52 | 5 | 7 |

| S 50 C | 50 | 88 | 35 | 112 | 62 | 56 | 6 | 30 | 144 | 59 | 6 | 6 |

| S 60 C | 60 | 100 | 44 | 137 | 70 | 66.8 | 6 | 38 | 167.5 | 72.5 | 8 | 6 |

| S 70 C | 70 | 115 | 49 | 161 | 80 | 77.8 | 6 | 42 | 195 | 86 | 10 | 6 |

| S 80 C | 80 | 141 | 55 | 180 | 95 | 89.4 | 6 | 47 | 231 | 98 | 10 | 6 |

Introducing Honed Tubes from MS Trading—engineered for flawless performance in hydraulic and pneumatic cylinders. These tubes offer precise inner diameter finishes, high straightness, and outstanding roundness, making them ideal for high-pressure applications.

Available Types:

Tolerances:

Surface Finish:

Lengths Supplied:

Steel Grade | Condition | Tensile Strength<br>(Rm, MPa) | Yield Strength<br>(Rp0.2, MPa) | Elongation (%) | Impact Energy<br>KV @ -20°C (J) |

E355 (St52) | +SR | ≥620 (90,000) | ≥520 (75,000) | ≥15 | ≥27 |

E410 | +SR | ≥690 (100,000) | ≥590 (85,500) | ≥12 | ≥27 |

Steel Grade | C | Si | Mn | P (max) | S (max) | Al (min) | V (min) | Ti (max) |

E355 | ≤0.22 | ≤0.55 | ≤1.60 | 0.025 | 0.040 | ≥0.015 | ≥0.020 | – |

E410 | 0.16–0.50 | 0.10–1.00 | 1.30–1.70 | 0.030 | 0.035 | ≥0.01 | ≥0.08 | ≤0.05 |

OD (mm) | ID (mm) | Wall Thickness (mm) | Weight (kg/m) | ID Tolerance |

50 | 40 | 5.00 | 5.55 | H8 |

63.5 | 50.8 | 6.35 | 8.95 | H8 |

75 | 63 | 6.00 | 10.20 | H8 |

90 | 80 | 5.00 | 10.48 | H8 |

105 | 90 | 7.50 | 18.02 | H8 |

127 | 101.6 | 12.70 | 35.78 | H8 |

160 | 130 | 15.00 | 53.61 | H8 |

200 | 180 | 10.00 | 46.83 | H8 |

More than 200 sizes available from OD 35 mm to 355.6 mm. Full chart available on request

Welded Honed Tubes (DOM)

Hot Rolled Honed Tubes

SSID Ready-to-Use Tubes

Looking for top-quality honed tubes?

MS Trading delivers precision-engineered, ready-to-use honed tubes tailored for performance and longevity.

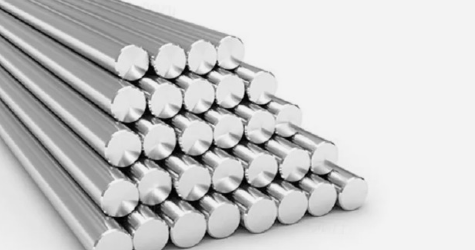

MS Trading proudly offers high-performance Chrome Plated Rods—crafted for critical industrial applications requiring exceptional surface finish, durability, and corrosion resistance. Engineered with premium carbon, alloy, and stainless steels, our chrome rods deliver superior wear resistance, high hardness, and dimensional accuracy—ideal for hydraulic cylinders, pneumatic actuators, and heavy-duty machinery.

Plating Grade | Chrome Layer | Corrosion Resistance (NSS) |

A-CHROME 15 | ≥15 μm | 120 hours / R9 Rating |

A-CHROME 20 | ≥20 μm | 200 hours / R9 Rating |

A-CHROME 30 | ≥30 μm | 200 hours / R9 Rating |

A-CHROME 40 | ≥40 μm | 500 hours / R9 Rating |

A-CHROME 50 | ≥50 μm | 500 hours / R9 Rating |

A-CHROME INOX | ≥20 μm (SS) | 1000 hours / R9 Rating |

Carbon & Alloy Steel:

Stainless Steel:

Material | Diameter (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation A5 (%) | Hardness (HB) | Impact KV (–20°C) |

C45E | ≤16 | ≥710 | ≥500 | ≥5 | ≈230 | — |

16–19.05 | ≥650 | ≥410 | ≥7 | ≈230 | — | |

19.05–100 | ≥580 | ≥305 | ≥16 | ≥180 | — | |

100–203.2 | ≥560 | ≥275 | ≥16 | ≥180 | — | |

20MnV6 | ≤19.05 | ≥700 | ≥620 | ≥10 | ≈200 | ≥27J |

19.05–90 | ≥550 | ≥450 | ≥18 | ≥163 | ≥27J | |

90–203.2 | ≥550 | ≥420 | ≥19 | ≥163 | ≥27J | |

38MnVS6 | ≤19.05 | ≥850 | ≥600 | ≥6 | ≥250 | — |

19.05–203.2 | ≥800 | ≥520 | ≥12 | ≥230 | — | |

CW85 | 20–140 | 850–1000 | ≥580 | ≥12 | ≥250 | — |

42CrMo4+QT | <16 | 1100–1300 | ≥900 | ≥9 | 298–350 | ≥27J |

16–40 | 1000–1200 | ≥750 | ≥11 | 350–380 | ≥27J | |

40–100 | 900–1100 | ≥650 | ≥12 | 290–340 | ≥27J | |

100–160 | 800–950 | ≥550 | ≥13 | 260–290 | ≥27J | |

160–203.2 | 750–900 | ≥500 | ≥14 | 250–280 | ≥27J |

Steel | Dia (mm) | Hardness (HRC) | Hardened Depth Range (mm) |

C45E | 6–203.2 | ≥55 HRC | 0.5 – 3.5 mm |

20MnV6 | 6–203.2 | ≥42 HRC | 0.5 – 3.5 mm |

38MnVS6 | 6–203.2 | ≥55 HRC | 0.5 – 3.5 mm |

42CrMo4 | 6–203.2 | ≥55 HRC | 0.5 – 3.5 mm |

Ø mm | Tolerance (f7) | Weight (Kg/m) |

12 | -0.016/-0.034 | 0.89 |

25 | -0.020/-0.041 | 3.85 |

40 | -0.025/-0.050 | 9.86 |

63 | -0.030/-0.060 | 24.46 |

100 | -0.036/-0.071 | 61.62 |

160 | -0.043/-0.083 | 157.75 |

203.2 | -0.050/-0.096 | 254.43 |

Full dimensional chart available on request.